happy embroidery machine troubleshooting

New Features in 216 from 214. FIXING SCREW HCM-812-30T MODEL 050.

Error And Measure Happy Hcs 1201 30 Maintenance Manual Page 199 Manualslib

Problem may re-occur without proper troubleshooting.

. Barudan Happy Toyota Tajima CNM USA LLC Technician. As new embroiderers get their machines and learn embroidery they are bound to have mishaps and mistakes. Used embroidery machines for sale.

Happy embroidery machine Part ES-M04-2945-1. Heres what to do for troubleshooting any threading issue. Beachs has been in business for many years and it shows.

Adjust head center upper stop needle depth hook timing hook spacing take up timing. Vacuum Cleaners-Repair Service Small Appliance Repair Household Sewing Machines. This referral is in the contracts that Brother has with their associate stores.

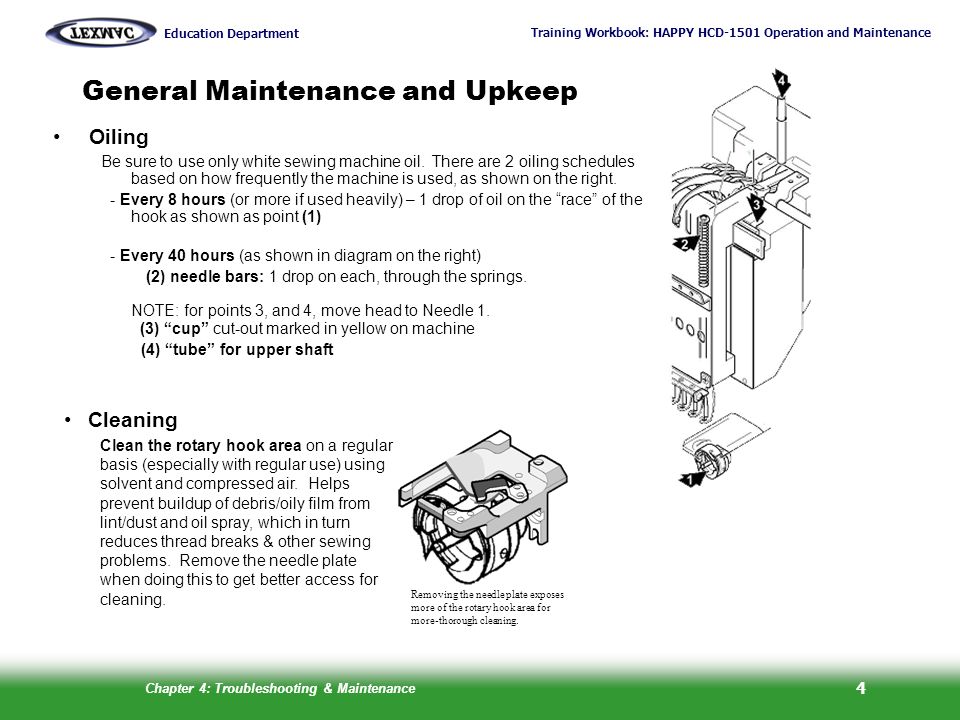

Refer to THIS THREADING DIAGRAM for your. Remove clean and de-burr rotary hooks. There may even be a certain sequence to follow to get your machine back on track.

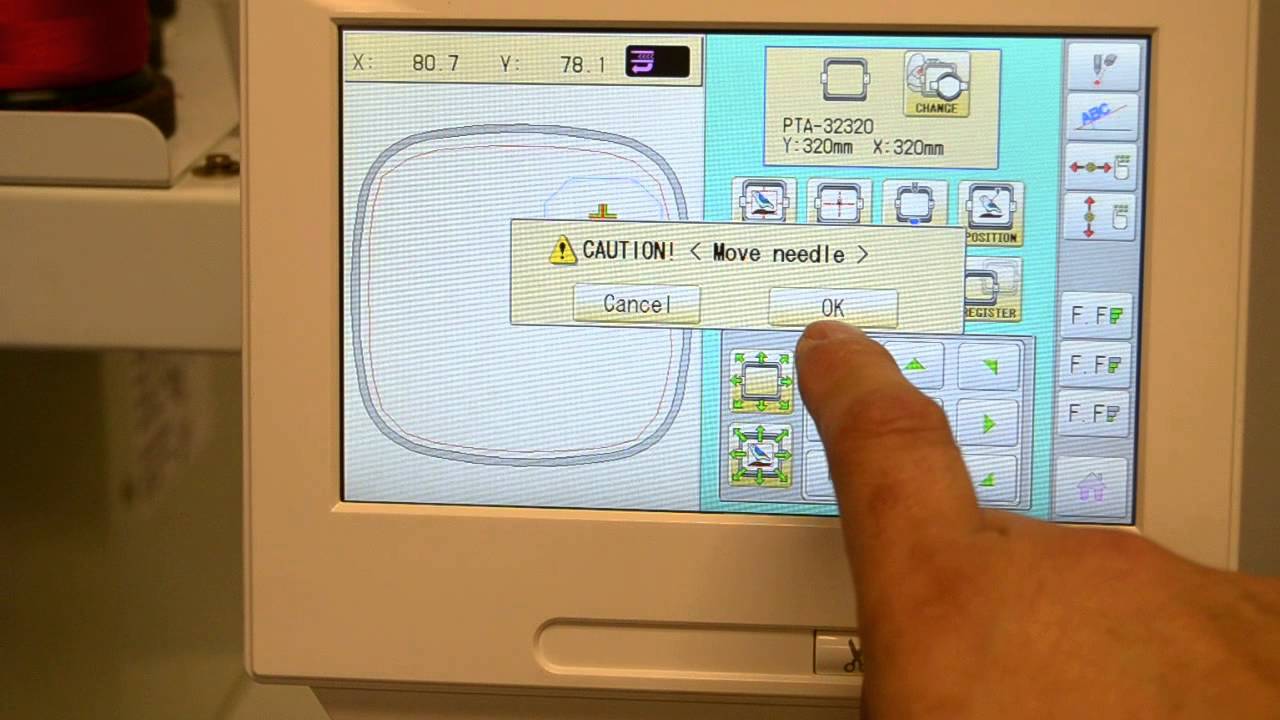

Webinar April 17 2019. HAPPY embroidery machines are very user-friendly with intuitive touchscreen. 35000 2000 shipping 2000 shipping 2000 shipping.

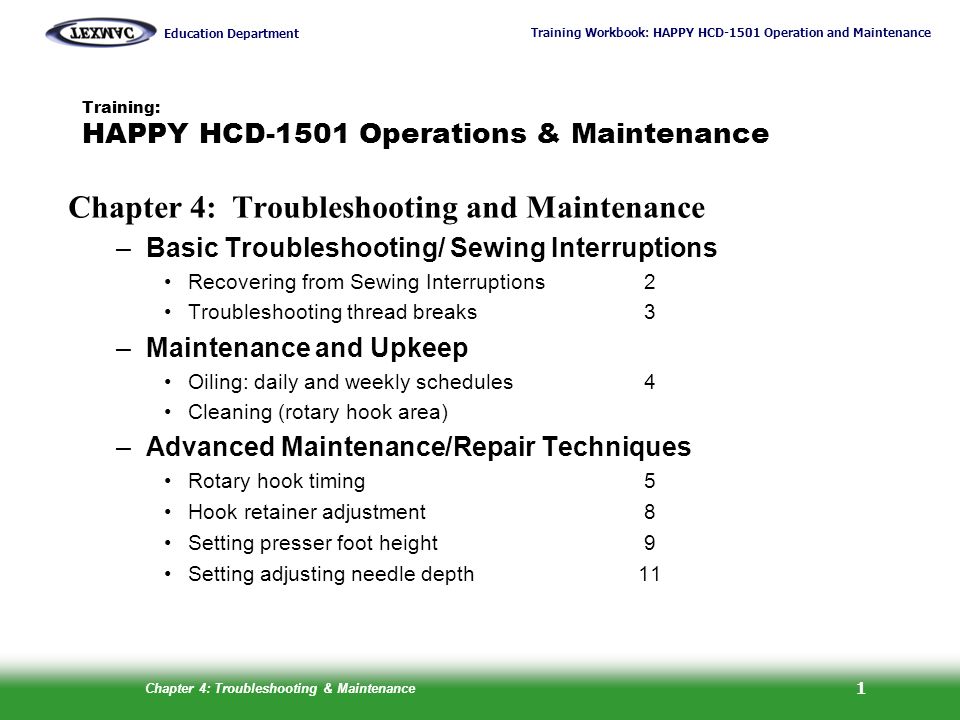

Very few button presses to load a design set it up and s. Most embroidery designs are digitized to be stitched with a 40 wt. In this webinar we go over some basic troubleshooting that can be done if your machine is having trouble cutting thread.

Remove the needle plate and bobbin case. Use a good quality 60 wt. As an authorized dealer for Baby Lock we carry a full line of sewing embroidery and serger machines in addition to providing guaranteed repair services and thorough machine training.

Do this by loosening each of the two 2 flathead screws with an offset screwdriver provided in the machine s toolkit Timing for HCS-1201. This sewing and quilting combo machine includes an advanced needle threading function that easily pushes the thread through the needle with the press of a. Single-head models include the 7-needle Journey the 12-needle Voyager and the 15-needle HCD2.

877-335-5206 The automated response will ask for your location before transferring to your Representative For repairs and assistance with your Happy Embroidery Machine contact our Machine Support Team. For more tips and tricks on embroidery visit our blog at httpswwwem. They will direct you to your nearest dealer for support of any kind.

Firmware 216 adds the following functions which can optionally be added to the shortcut buttons along the right. Do this using the keys on the control panel 3. If all the above basics are followed and thread breaks continue wherever the cone is placed that particular thread cone can be considered suspect.

FOR PARTS OR REPAIR. Embroidery is becoming popular as a hobby and a profitable business. Then re-install and reset hook timing New hooks will be installed if needed Trimmer wiper and picker mechanisms checked and reset to factory specs New parts will be installed if needed Inspect timing belts and axis belts check pantograph for smooth.

If the bottom thread looks problematic check the upper threading. This procedure does not address troubleshooting the cause of the break only to teach how to re-thread and continue sewing. All you have to do is find the correct stitch and start the embroidery machine again without having to readjust the machine.

Repair thread break by re-threading upper thread. To ensure the top thread is threaded correctly check to see that the presser foot is up when you are threading the machine. Watch this video to see how easy it is to operate any touch-screen model Happy embroidery machine.

Press TCUT to cut thread still attached to garment2. When you discover an embroidery problem that you need to correct take note of the exact poin t in the design where the error occurred. Do this by loosening each of the two 2 flathead screws with an offset screwdriver provided in the machines toolkit 3.

Check that the thread is properly routed at all points. See how intuitive the touch screen controller is to set up and embroider. These threads can withstand the heat and friction that is associated with the high speeds of the embroidery process.

Winter Park FL Phone. Melco Stellar 1 Controller Keyboard for Embroidery Machine FOR PARTS OR REPAIR. Power the machine on and allow it to continue to the main drive screen.

Na Preferred Method of Contact. FOR PARTS OR REPAIR. Basic Machine Embroidery Troubleshooting Help.

Happy embroidery machine Part ES-M04-2945-1. The people who own and work there are very knowledgeable and want to help you any way. Use a good quality embroidery thread designed specifically for machine embroidery.

Engineered and manufactured in Japan HAPPY machines are known for their quality and durability and are backed by industry-leading support and training from TEXMAC Direct. Select needle six 6. Watch the embroidery process from start to finish using HAPPY embroidery machines.

Use The Correct Needles Be sure to select the. If the top thread doesnt look good check the bobbin threading. Use quality 40-wt polyester or rayon embroidery thread.

If the thread is actually broken then. Maybe a design problem if breaks in the same places. Have the digitizer fix the bad section or run a design cleanup to remove short stitches.

You can call or contact Brother but they will not help you with machine problems. Select needle seven 7Do this using the keys on the control panel 3. At least you will have a reference to restart the embroidery.

Power the machine on and allow it to continue to the main drive screen. FL GA Machines Serviced. Remove the bobbin case.

Barudan DJR Embroidery Services Technician. Thread in the bobbin. Turn on the Stitch Sweeper and reload the design or 2.

If pathfeed is not the cause then. If you would like to learn more about the Happy Embroidery Machines call our Sales Representatives. Deborah Jones shows you what could be causing thread breaks and how to correct them.

Here are some simple tips to keep in mind while sewing on your embroidery machine. Firmware 216 is posted for all current touch screen model HAPPY machines including single-head models HCD2-1501 HCS2-1201 Voyager and HCH-701 Journey and all current touchscreen multi-head models. Cincinnati Sew Vac.

Remove the needle plate and bobbin case.

Happy Hcs 1201 30 Manuals Manualslib

Texmac Direct Homepage Happy Multi Needle Embroidery Machines

Webinar April 17 2019 Troubleshooting The Knife System Youtube

Hcd 1 Head Embroidery Machine Happy Multi Needle Embroidery Machines

Hcd 1501 User S Manual Happy Multi Manualzz

Hcd 1501 40 Happy Embroidery Machines Manualzz

Troubleshooting Embroidery Thread Breaks Youtube

Training Happy Hcd 1501 Operations Maintenance Ppt Video Online Download

Oiling Your Happy 12 Needle Voyager Machine Youtube

Training Happy Hcd 1501 Operations Maintenance Ppt Video Online Download

Legacy Happy Multi Needle Embroidery Machines

Hcr Multi Head Embroidery Machine Support Happy Multi Needle Embroidery Machines

Training Happy Hcd 1501 Operations Maintenance Ppt Video Online Download

Journey 1 Head Embroidery Machine Happy Multi Needle Embroidery Machines

014 Preparing To Sew Sewing And Tenson Check Adjustment Youtube

April 2019 Webinar Troubleshooting The Cut System Happy Multi Needle Embroidery Machines

You And Your Sewing Machine C T Publishing

Troubleshooting Resources For Hcd 1501 15 Needle Touchscreen Machine Happy Multi Needle Embroidery Machines